Each cell in the li ion battery stack produces 3 0v to 3 9v depending on its state of charge discharge.

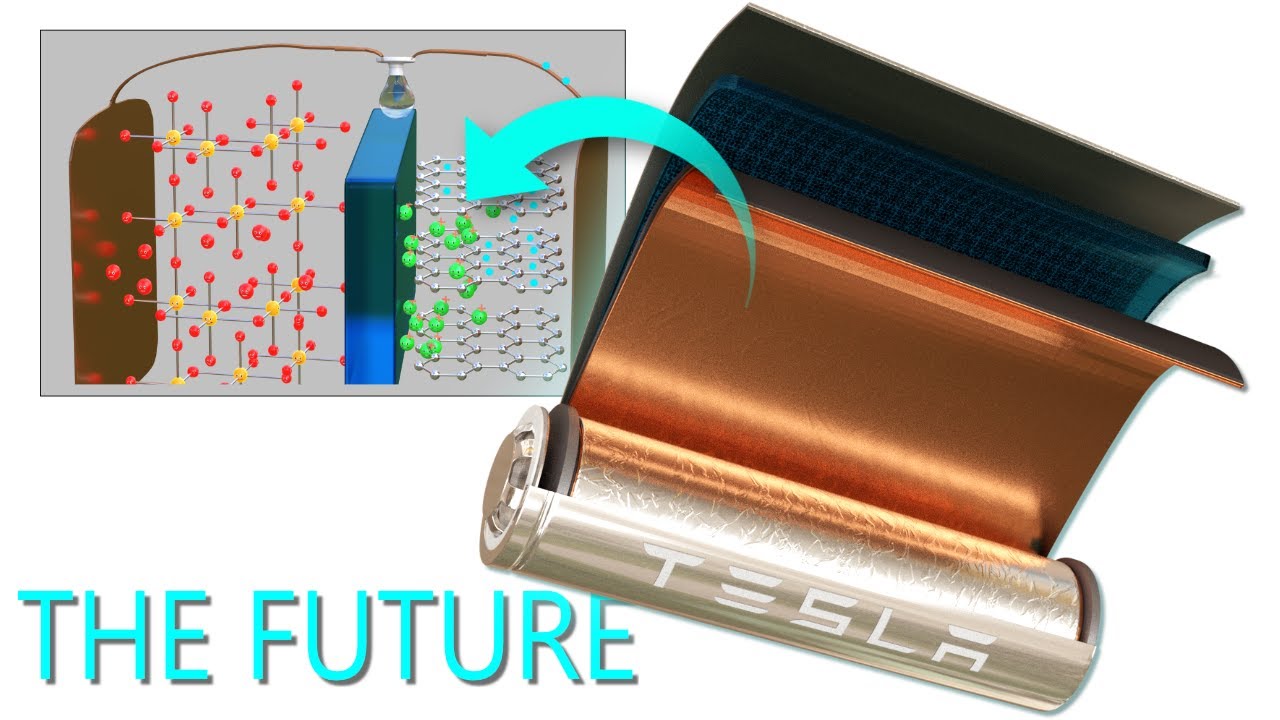

Lithium ion battery cells for automotive applications.

Figure 1 shows one version of an hev power train.

Such cells provide a relatively light and small source of energy and are now manufactured in very large quantities 1 billion cells per year in an automotive application a lithium ion battery consists of tens to thousands of individual cells packaged together to provide the.

Stanley whittingham rachid.

Modeling and analysis cost modeling of lithium ion battery cells for automotive applications gae tan patry1 2 3 alex romagny3 se bastien martinet2 daniel froelich1 1lcpi arts et metiers.

Although the quality of battery fabrication has improved guarding against higher temperature and fault conditions in any automotive application remains crucial for reliable operation.

A prototype li ion battery was developed by akira yoshino in 1985 based on earlier research by john goodenough m.

This topic has already been the subject of some studies but although of primary importance the role on cost of a cell design parameter the.